GRAVITY GOODS ROPEWAY

Regular lay means the wires in the strands

are laid opposite in direction to the lay of

the strands. Lang’s lay means that wires are

laid in the same direction as the strands

are laid. Mostly, right hand regular lay

wire rope is used for gravity ropeway. This

specification meets the requirements of

most of the applications and equipments.

The other lay specifications are considered

as exceptions and are not widely used

except for very specific purposes.

Therefore, particular specifications must

be requested when ordering wire ropes.

Normally, manufacturers do not tend to

produce specific types of wire ropes in

small quantities.

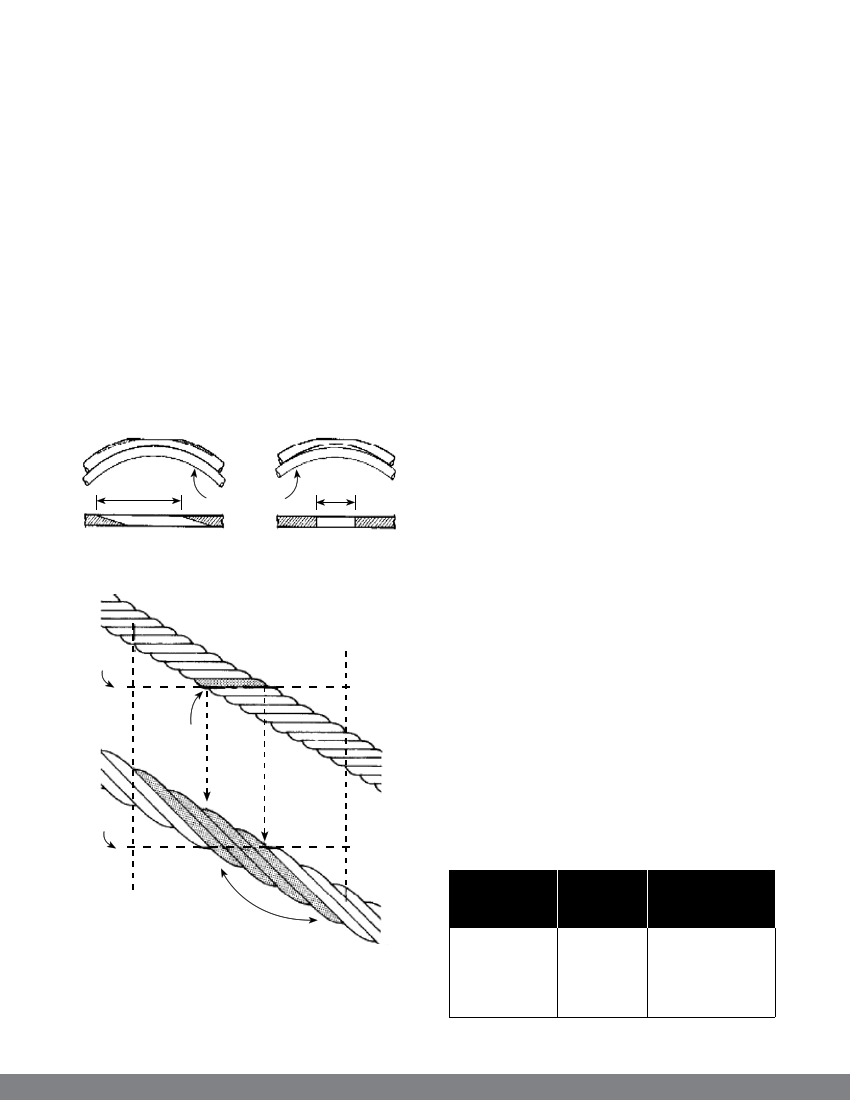

WEAR AREA

LANG

Supporting

inner wire

WEAR

AREA

regular

Rope

axis

a

Full wire

Regular Lay strand

b

Rope

axis

a

lang Lay strand

b

4 Full wires

Difference in abrasion characteristics

of Lang’s Lay and Ordinary lay ropes

Glossary of Terms Used

The differences between Lang’s lay and

ordinary lay wire ropes are:

1. the number of strands,

2. the construction of strands,

3. the size of the core,

4. the lay direction of the strand versus the

core, and

5. the grade of the carbon steel of the

wires.

N.B. Lang’s lay ropes are preferred over the

ordinary lay for the gravity ropeways because

it offers more contact area between the wire

and the bearing surface which increases the

abrasion resistance of the rope as compared

to an equivalent ordinary lay rope. Besides, it

is more flexible than the ordinary rope with

more resistant to bending fatigue resulting to

longer service life than the ordinary lay wire

rope.

13. Galvanisation: Galvanisation means zinc

coating of the wires, as the wire ropes are

exposed to the external environment all the

time, galvanisation is required to prevent it

from potential corrosion and rust. The extent

of galvanisation depends on the frequency

of the rope usage. There are two methods of

galvanising:

1. Galvanising after the finished wire has

been drawn, and

2. Galvanising before the wire is sent for

drawing.

The specification of zinc coating is IS:

4826/68 and API-STD 9A.

Weights of coatings are:

Wire ømm

1.25 – 1.40

1.40 – 1.60

1.60 – 1.80

1.80 – 2.24

2.24 – 2.80

Heavy Coatings,

gm/m2

“A-type”

180

190

200

210

230

Medium Coatings,

gm/m2

(Z –Type)

90

95

95

105

110

133